COMPANY NEWS

In October 2016, the 180t RH vacuum system transformation project of Shagang Group Zhangjiagang Rongsheng Steelmaking Co., Ltd. converter second workshop undertaken by Zhejiang Hangzhen Energy Technology Co., Ltd. was successfully completed. After the transformation, the system performance fully meets or exceeds the original VAI design and saves energy. The effect is remarkable and highly praised by users.

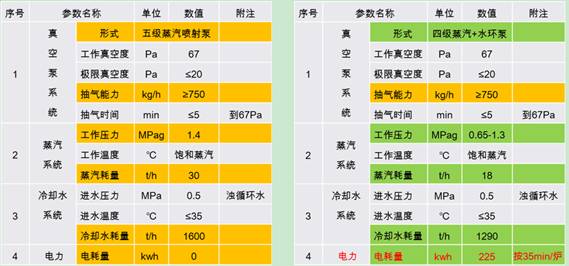

This vacuum system design adopts the current international advanced vacuum system scheme, which is composed of a four-stage steam jet pump + water ring vacuum pump. Compared with the original five-stage steam jet pump, the vacuum system is composed of a four-stage steam jet pump + water ring vacuum pump. Energy saving is more than 30%, reduced from the original 24t/h to the current 16t/h, and the operation is convenient and the operation is reliable.

表1:改造前系統(tǒng)參數(shù) 改造后系統(tǒng)參數(shù)

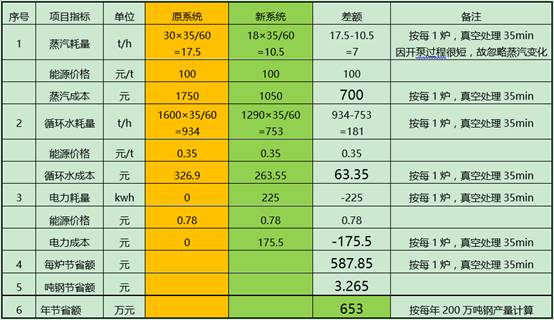

After the 180t RH vacuum system transformation project in the second workshop of the converter is put into use, the replaced 2# RH vacuum pump system can fully meet the normal production at about 8bar, and the actual steam consumption is less than 18t/h, which meets the energy-saving index requirements. After the transformation, the vacuum pump can use the existing low-pressure steam in the plant area to meet the production requirements of the RH furnace, without additional access to a steam source above 14bar, and rationally utilize the low-pressure waste heat resources; after the transformation, the steam consumption of the vacuum pump is based on the original steam The consumption can save at least 7t per hour, and the annual steam cost can be saved by more than 6 million yuan.

Shagang users are very satisfied with the system performance and energy-saving effect after the transformation. At present, Shagang Group

The energy-saving transformation project of 1#RH system is being installed and debugged by Hangzhen Energy.